3D printing enables the creation of bioabsorbable implants by offering design freedom and material options that traditional manufacturing processes cannot match These implants provide temporary support during healing and then safely dissolve in the body.

Key aspects of creating bioabsorbable implants using 3D printing:

Design Freedom

3D printing facilitates complex infill geometries like gyroid and honeycomb patterns, which can alter mechanical properties and cellular infiltration.

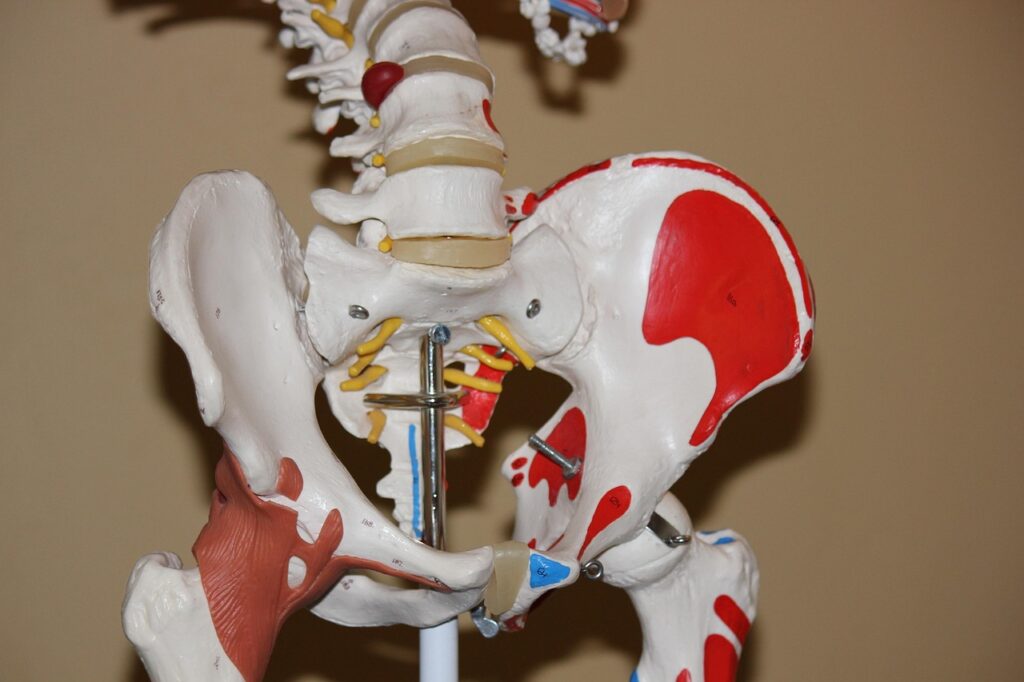

Customization

Patient-specific implants can be designed based on the patient’s anatomy.

Materials

Bioresorbable materials can be used to 3D print implants that degrade over time. Poly-Med’s Photoset® resin product line utilizes monomeric constituents that have been used in medical devices for over forty years and are anticipated to be biocompatible.

Eliminating additional surgery

Bioabsorbable implants can eliminate the need for a second surgery to remove the implant.

How do bioabsorbable implants reduce the need for secondary surgeries ?

Bioabsorbable implants reduce the need for secondary surgeries because they are made from biocompatible materials that the body safely absorbs over time. These materials dissolve, eliminating the need for surgical removal. This reduces stress and suffering for the patient, and accelerates rehabilitation.

Additional benefits of bioabsorbable implants:

Reduced complications

The risk of complications like infection and implant loosening is much diminished because there is no need for a second procedure to remove the implant.

Natural healing

They support and facilitate the natural healing process by providing temporary structural support. As the implant gradually degrades, it allows the patient’s own tissues to regenerate, promoting a more natural and robust recovery.

Stress shielding

Traditional metal implants can remove stress from the bone, leading to a weakening effect called stress shielding. Bioabsorbable implants allow stress to gradually return to the bone as they dissolve, strengthening the bone and accelerating rehabilitation.

Applications

Bioabsorbable implants can be used for fracture fixation, ligament and tendon repair, spinal surgery, and joint replacements.

Child patients

Bioabsorbable implants are particularly beneficial for children, as they eliminate the need for additional operations to prevent harm to natural bone growth.

Materials

Bioabsorbable implants are made from materials like polyglycolic acid (PGA), polylactic acid (PLA), or copolymers. Bioretec’s Activa-series implants are made from poly L-lactide-co-glycolide copolymer (PLGA), which metabolizes into carbon dioxide and water. Bioretec’s RemeOs™ series resorb through oxidation to Magnesium-, Calcium- and Zinc-minerals.

Environmentally Sustainable

Bioabsorbable implants reduce the environmental burden associated with the production, transportation, and disposal of traditional non-biodegradable implants.

Sources

https://3dincredible.com/the-evolving-landscape-of-3d-printed-implant-technology/

https://www.ntop.com/resources/blog/3d-printing-implants-a-complete-guide/

https://poly-med.com/bioresorbable-materials-3d-printing-implantable-medical-devices/